Understanding Earth Meters: A Comprehensive Guide

In the domain of electrical safety and maintenance, the Earth meter stands as a crucial tool. Proper grounding of electrical systems is important for ensuring safety, preventing electrical shocks, and protecting sensitive equipment from electrical surges. This comprehensive guide dives into the complications of Earth meters, their importance, functionality, types, and applications in various industries.

What is an Earth Meter?

An Earth meter, also known as a ground resistance tester, is an instrument designed to measure the resistance of the ground in electrical grounding systems. Grounding systems are essential for providing a path of least resistance for electrical currents to dissipate safely into the earth. This protects both people and equipment from the adverse effects of electrical faults and lightning strikes.

The Importance of Ground Resistance Measurement

Measuring ground resistance is critical for several reasons:

- Safety Assurance: Ensuring low resistance paths to the ground prevents electrical shock hazards.

- Equipment Protection: Proper grounding protects electrical equipment from damage due to power surges and lightning strikes.

- Compliance with Standards: Regular ground resistance testing helps in complying with national and international safety standards.

- System Performance: It ensures the effective operation of electrical systems, minimizing downtime and maintenance costs.

How Does an Earth Meter Work?

An Earth meter typically operates by injecting a known current into the ground and measuring the resulting voltage drop. This process allows for the calculation of ground resistance using Ohm’s Law (Resistance = Voltage / Current). There are several methods for measuring ground resistance, including the fall-of-potential method, the clamp-on method, and the selective method.

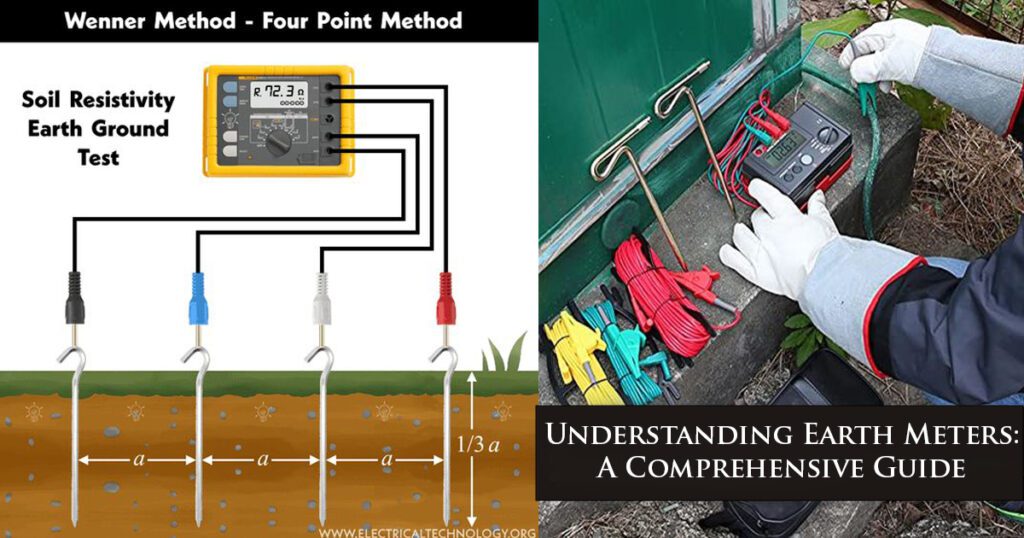

Fall-of-Potential Method

This is the most common method used for ground resistance measurement. It involves driving two auxiliary electrodes into the ground at specific distances from the grounding electrode and measuring the voltage drop between them. The resistance is then calculated based on the known current and measured voltage.

Clamp-On Method

The clamp-on method is a more convenient and less invasive technique. It uses a clamp-on ground resistance tester that induces a current into the ground system and measures the resulting voltage drop without the need for auxiliary electrodes. This method is particularly useful for testing in urban areas where driving electrodes into the ground is not feasible.

Selective Method

The selective method combines elements of the fall-of-potential and clamp-on methods. It uses an auxiliary electrode and a clamp-on meter to measure the resistance of individual grounding electrodes within a complex grounding system without disconnecting the grounding conductor.

Types of Earth Meters

Earth meters come in various types, each suited to specific applications and measurement methods. Here are the most common types:

Digital Earth Testers

Digital Earth testers are advanced instruments that provide precise measurements of ground resistance. They come with digital displays, making it easy to read and interpret the results. These testers often include features like data logging, GPS tagging, and connectivity options for downloading measurement data.

Analog Earth Testers

Analog Earth testers are traditional devices that use needle indicators to show resistance values. While they are less common today, they are still used in certain applications where digital devices may not be suitable.

Clamp-On Earth Testers

Clamp-On Earth testers are ideal for quick and non-intrusive measurements. They are designed to clamp around a grounding conductor or rod and measure resistance without the need for auxiliary electrodes. These testers are perfect for use in urban environments and in systems with multiple grounding points.

Applications of Earth Meters

Earth meters are used across various industries to ensure electrical safety and system integrity. Here are some key applications:

Power Generation and Distribution

In the power generation and distribution sector, ensuring effective grounding is crucial for protecting infrastructure and maintaining reliable service. Earth meters are used to regularly test and monitor grounding systems at substations, power plants, and distribution networks.

Telecommunications

Telecommunications equipment is highly sensitive to electrical disturbances. Proper grounding is essential to prevent damage and ensure the smooth operation of communication networks. Earth meters help in testing and maintaining the integrity of grounding systems for telecom towers and facilities.

Industrial Facilities

Industrial facilities with heavy machinery and complex electrical systems rely on effective grounding to prevent equipment damage and ensure worker safety. Regular ground resistance testing with Earth meters is a key part of their maintenance routines.

Construction Sites

Temporary electrical installations at construction sites require effective grounding to ensure the safety of workers and equipment. Earth meters are used to test the ground resistance of temporary grounding systems before and during construction activities.

Residential and Commercial Buildings

Ensuring proper grounding in residential and commercial buildings is essential for preventing electrical hazards and protecting occupants. Earth meters are used by electricians and maintenance personnel to test and verify the effectiveness of building grounding systems.

Best Practices for Using Earth Meters

To achieve accurate and reliable ground resistance measurements, it is important to follow best practices when using Earth meters:

- Regular Calibration: Ensure that the Earth meter is regularly calibrated according to the manufacturer’s recommendations to maintain accuracy.

- Proper Placement of Electrodes: When using methods that require auxiliary electrodes, ensure they are placed at the correct distances and in suitable ground conditions.

- Environmental Considerations: Be aware of environmental factors such as soil moisture, temperature, and composition, which can affect resistance measurements.

- Safety Precautions: Always follow safety guidelines to prevent electrical hazards while conducting tests.

Conclusion

The Earth meter is an indispensable tool for ensuring the safety and reliability of electrical systems. By providing accurate measurements of ground resistance, it helps in preventing electrical shocks, protecting equipment, and maintaining compliance with safety standards. Whether in power generation, telecommunications, industrial facilities, construction sites, or residential and commercial buildings, the Earth meter plays a vital role in maintaining electrical safety and system integrity.

FAQ’s

1. What is the primary function of an Earth meter?

The primary function of an Earth meter is to measure the resistance of the ground in electrical grounding systems. This measurement ensures that the grounding system provides a safe and effective path for electrical currents to dissipate into the earth, which helps in preventing electrical shocks and protecting equipment from surges and faults.

2. How often should ground resistance be tested with an Earth meter?

The frequency of ground resistance testing depends on the specific application and environmental conditions. For critical installations, such as power plants and telecommunications facilities, it is recommended to perform tests at least annually. In less critical applications, testing every two to three years may be sufficient. Regular testing ensures that the grounding system remains effective and complies with safety standards.

3. What factors can affect the accuracy of ground resistance measurements?

Several factors can impact the accuracy of ground resistance measurements, including soil composition, moisture content, temperature, and the placement of auxiliary electrodes. To ensure accurate readings, it is important to consider these environmental factors and follow best practices, such as proper calibration of the Earth meter and correct placement of electrodes.

4. Can Earth meters be used in urban environments with limited space?

Yes, clamp-on Earth meters are particularly suitable for use in urban environments where space is limited. These devices allow for non-intrusive measurements by clamping around a grounding conductor or rod, eliminating the need for auxiliary electrodes and extensive ground space. This makes them ideal for testing grounding systems in densely populated areas.

5. What are the key differences between digital and analog Earth meters?

Digital Earth meters provide precise measurements with easy-to-read digital displays and often include advanced features like data logging, GPS tagging, and connectivity options. Analog Earth meters, on the other hand, use needle indicators to show resistance values and are generally simpler in design. While digital meters offer more functionality and convenience, analog meters may still be used in certain applications where digital devices are not suitable.